What is an incremental rotary encoder? An incremental rotary encoder converts spinning motion into electrical signals, playing a crucial role in tracking movement in robots and machines. It measures position and speed by generating digital pulses. Due to its simple design and affordability, it is widely utilized. In 2023, incremental rotary encoders accounted for 58% of the market. They are frequently found in CNC machines, conveyor belts, and wind turbines.

Key Takeaways

- Incremental rotary encoders change spinning movement into digital signals. They help track position, speed, and direction in machines.

- These encoders are affordable and easy to use. This makes them great for robots, CNC machines, and conveyor belts.

- Incremental encoders need a starting point to find position after losing power. Absolute encoders, however, keep position data even without power.

- They give live updates on motion, improving control in industries like manufacturing and energy.

- Picking the right encoder type (optical, magnetic, or capacitive) is important. The choice depends on the environment and how accurate it needs to be.

What is an Incremental Rotary Encoder?

Definition and purpose

An incremental rotary encoder changes spinning motion into digital signals. It tracks position, speed, and direction by creating pulses. These pulses are made when a disk spins through a sensor. The pulses show movement, making it great for speed or position tracking. Unlike absolute encoders, incremental ones lose position data when turned off. They need a starting point to find exact positions again.

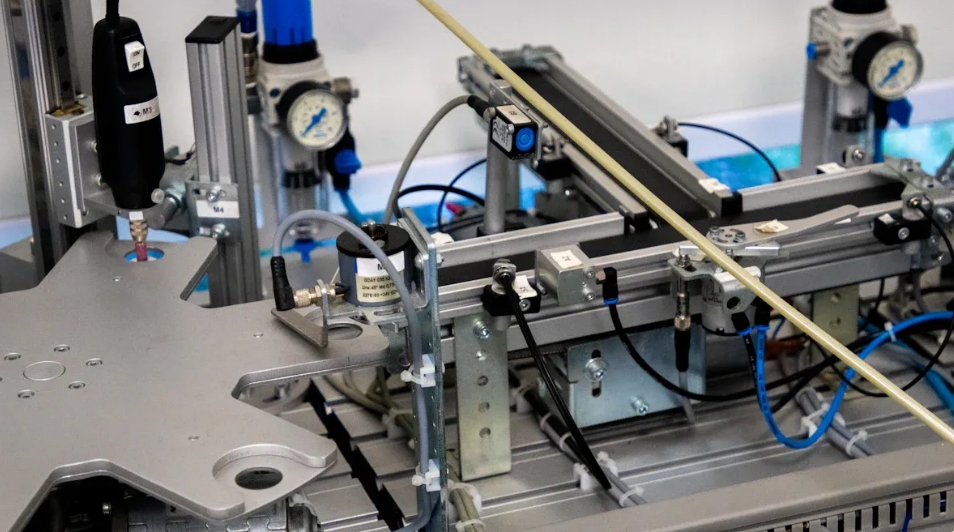

These encoders are very important in automation systems. They are used in robots, CNC machines, and conveyor belts to control motion. Their small size and low cost make them a favorite in industries needing accuracy and savings.

Key differences from absolute encoders

Incremental encoders and absolute encoders store position data differently. Absolute encoders give a unique position for every rotation angle, even after power loss. Incremental encoders only track changes in position. They need a starting point to find exact positions after being turned on.

| Encoder Type | Typical Accuracy | Maximum Accuracy |

|---|---|---|

| Absolute Optical | 0.18 degrees | 0.25 degrees |

| Incremental Optical | ~0.18 degrees | N/A |

Incremental encoders are simpler and cheaper than absolute encoders. They work best for tasks needing relative motion tracking, like speed or direction sensing.

Overview of its role in motion control

Incremental rotary encoders are key in motion control systems. They give real-time updates on position and speed. This helps control motors and machines precisely. For example:

- Robotic Arms: Encoders check joint angles and speeds for accurate movements.

- Conveyor Belts: They track speed and position for smooth product handling.

- Wind Turbines: Encoders measure speed to adjust blades and boost energy.

By turning motion into signals, these encoders improve how machines work in many industries.

How Does an Incremental Rotary Encoder Work?

How incremental encoders work

An incremental encoder changes spinning motion into digital signals. It has a spinning disc with clear and dark sections. A light, like an LED, shines on the disc as it spins. A sensor checks if the light passes through or gets blocked. This creates pulses that show the disc’s movement. Each pulse equals a small turn of the disc, helping track rotation.

The encoder measures motion in steps, not exact positions. This makes it great for checking speed, direction, or movement changes.

Turning motion into signals

The process starts with a spinning disc on the encoder’s shaft. As the shaft spins, the disc’s slots line up with the light and sensor. When light passes through a slot, the sensor makes a HIGH signal. If the slot blocks the light, the signal becomes LOW. This back-and-forth pattern creates pulses sent to a controller.

The number of pulses depends on how fast the disc spins. Faster spins make more pulses, allowing accurate motion tracking. For example, in optical encoders, the light and sensor work together to make precise signals showing the disc’s movement.

Making pulses and sending signals

The encoder’s output looks like square waves. These waves are the pulses made by the spinning disc. Some encoders have one channel (A), two channels (A and B), or an extra index pulse (Z). Two-channel encoders also show the rotation direction.

| Parameter | What It Means |

|---|---|

| Output Signal Type | A for one channel, A and B for two channels, Z for index pulse |

| Pulse Count | Pulses per turn (PPR) and counts per turn (CPR) |

| Rise Time | Time to go from low to high; usually <= 500ns |

| Fall Time | Time to go from high to low; usually <= 100ns |

| Frequency Response | Fastest rate the sensor can switch; usually < 300kHz |

The pulses help track and control motion in real-time. This makes incremental encoders important for motors, robots, and factory machines.

Components of an Incremental Rotary Encoder

Rotating disk and its function

The rotating disk is the main part of an incremental encoder. It helps measure movement by making pulses when light is blocked. The disk has clear and dark sections. As it spins, these sections work with a light and sensor to create signals. Each dark section gives many reference points, improving accuracy.

In a quadrature encoder setup, the disk also detects direction. Two sensors read the disk’s movement to tell if it spins clockwise or counterclockwise. This makes the disk important for tracking motion in motors and robots.

Sensor or detector mechanism

The sensor in an incremental encoder creates accurate signals. It has a light source, like an LED, and a detector. The light shines through the spinning disk, and the detector reads where the light is blocked. This makes signals that show the disk’s movement.

The sensor’s accuracy depends on the disk’s design. Quadrature encoders use lines on the disk to make four reference points. This improves resolution and shows direction based on signal order. The sensor is key for keeping the encoder precise in detailed tasks.

Signal processing and output system

The signal system turns raw signals into useful data. The sensor sends signals to a circuit that cleans them up. The circuit removes noise and sends square wave signals to controllers.

Some encoders use advanced circuits to improve performance. For example, FPGA circuits can increase counts per turn for better resolution. These systems make the encoder fast and reliable for motion control.

| Specification Type | Details |

|---|---|

| Electrical specifications | Voltage, current needs, ripple, output type, max frequency, commutation format, accuracy, interpolation factors |

| Environmental specifications | Storage and operating temperature, IP rating, humidity, vibration, shock |

| Mechanical specifications | Shaft size, tolerance, engagement, movement limits, mounting, adjustment range, inertia |

These parts work together to make the encoder accurate and efficient. This makes it a trusted tool for many industries.

Types of Incremental Rotary Encoders

Optical incremental encoders

Optical encoders use light to track movement. A spinning disk with clear and dark parts works with a light and sensor. As the disk turns, the sensor notices light changes and makes pulses. These pulses show how the encoder shaft moves. Optical encoders are very accurate, making them great for tasks needing exact measurements.

| Metric | What It Means |

|---|---|

| Resolution (CPR) | Counts cycles per turn. Ranges from 32 to over 10,000 CPR. |

| Scalability | Can boost resolution using interpolation methods. |

| Jitter and Signal Quality | Higher resolutions may lower signal quality due to jitter. |

Optical encoders work best in clean places. But they can have trouble with dirt or dust blocking the light. This is important to think about when picking an encoder for factories or outdoor use.

Magnetic incremental encoders

Magnetic encoders use magnets to measure motion. A magnetized disk and sensor create pulses as the disk spins. These encoders are tough and can handle dirt, dust, and water. They are perfect for rough environments like outdoors or factories.

Benefits of magnetic encoders:

- Resist dirt, dust, and water.

- Strong and long-lasting.

- Small designs with built-in electronics.

Drawbacks of magnetic encoders:

- Less accurate than optical encoders.

- Can be affected by magnetic or radio interference.

- Sensitive to temperature changes.

To reduce noise, use shielded cables and ground wires properly. Keeping other electrical devices away from the encoder also helps it work better.

Capacitive incremental encoders

Capacitive encoders track motion by sensing changes in capacitance. A spinning disk changes the electric field between plates, creating pulses. These encoders are small and resist dirt and dust. They are great for jobs needing lightweight and strong tools.

| Specification | What It Means |

|---|---|

| Outer diameter | Size depends on what it’s used for. |

| Shaft type and diameter | Made to fit with mechanical systems. |

| Pulse count | Shows how detailed the encoder’s resolution is. |

Capacitive encoders are less common than optical or magnetic ones. But their ability to resist dirt and dust makes them a good choice for tough environments.

Advantages of Incremental Rotary Encoders

High resolution and accuracy

Incremental encoders are great for precise motion control tasks. They can track tiny movements with high resolution. The resolution depends on the pulses made per turn, which can be thousands. For example, optical encoders often have 0.18-degree accuracy, with a maximum of 0.25 degrees.

The encoder’s design and parts affect its accuracy. If the lines on an optical disk vary in size, timing errors can happen. Calibration helps fix these errors for better performance. These encoders can even measure position errors in arcminutes, showing their precision.

| Encoder Type | Resolution (counts/positions per turn) | Typical Accuracy (degrees) |

|---|---|---|

| Incremental Encoder | Counts per turn | Depends on system setup |

| Absolute Single-Turn | Positions per turn | 0.18 degrees (10.8 arcminutes) |

| Multiturn Encoder | Positions per shaft turn | 0.25 degrees (15 arcminutes) |

Cost-effectiveness and simplicity

Incremental encoders are cheaper and easier to use than absolute ones. They make pulses to show movement but don’t track exact positions. This simple design lowers costs and makes them easy to maintain. They are a budget-friendly choice for many uses compared to absolute encoders.

Their simple design also makes them easy to add to systems. For instance, they are often used in conveyor belts and robotic arms. This ease of use makes them popular in industries where saving money and simplicity matter most.

Versatility in various applications

Incremental encoders work well in many different jobs. They are used in factories, home gadgets, and cars. In wind turbines, they measure blade speed to improve performance and prevent damage. In factories, they help control conveyors and robotic arms.

These encoders measure speed and direction accurately, making them useful in many places. Whether it’s CNC machines, 3D printers, or motor systems, incremental encoders give reliable feedback to boost precision and efficiency.

Applications of Incremental Rotary Encoders

Industrial automation and robotics

Incremental rotary encoders are important in factories and robots. They measure spins, angles, and positions to give accurate motion feedback. In robotic arms, encoders track joint movements for smooth and precise actions. In machines, they monitor speed and direction for reliable performance.

Encoders are needed in fast and complex systems. They help conveyors keep steady speeds and robots perform exact tasks. Their role in automation keeps growing as industries need dependable tools.

Market Insight:

In 2023, rotary encoders made up 58% of the market. Their low cost and accuracy make them popular in robots and conveyor systems.

CNC machines and 3D printers

CNC machines and 3D printers use encoders for accuracy. In CNC machines, encoders check tool positions and speeds for perfect designs. In 3D printers, they track print head movements for even layers.

Encoders improve how these machines work. They turn spinning motion into signals for controllers. This helps create high-quality results. Their simple design and low price make them great for factories and hobbyists.

Motor control and feedback systems

Encoders are key for motor control systems. They turn motor shaft spins into signals to track speed and position. This is useful for robots, CNC machines, and factory equipment.

Encoders give good feedback for smooth motor operation. They are affordable and work well in tough environments. For example, in conveyor belts, encoders keep speeds steady to boost productivity.

Did You Know?

Incremental encoders were the top choice in 2022. They are widely used in motor systems and factory automation.

Incremental rotary encoders change spinning motion into digital signals. Do you know what an incremental rotary encoder is? It measures movement, speed, and direction accurately. This makes it very useful in automation and motion control systems. Its simple design and low cost make it popular in industries like robotics, factories, and energy.

Using these encoders can improve how your systems work. Learn about their uses to discover new ways to control motion and automate tasks.

FAQ

What is the difference between PPR and CPR in incremental encoders?

PPR means Pulses Per Revolution, and CPR stands for Counts Per Revolution. PPR shows how many pulses happen in one full turn. CPR counts both the rising and falling edges of the signal. This makes CPR double the count compared to PPR.

Can incremental encoders measure absolute position?

No, incremental encoders cannot measure absolute position. They only track position changes. If power is lost, the encoder needs a reset to a reference point to work correctly again.

How do you determine the resolution of an incremental encoder?

To find the resolution, divide 360 degrees by the Pulses Per Revolution (PPR). For example, if an encoder has 1,000 PPR, its resolution is 0.36 degrees per pulse.

Are incremental encoders suitable for harsh environments?

Yes, but the type matters. Magnetic and capacitive encoders resist dirt, dust, and moisture better than optical ones. Pick the right encoder for your environment.

What are the common output signals of incremental encoders?

Incremental encoders make square wave signals. Common outputs include:

- A: Main signal

- B: Second signal for direction

- Z: Index pulse for reference

These signals help track speed, direction, and position changes.